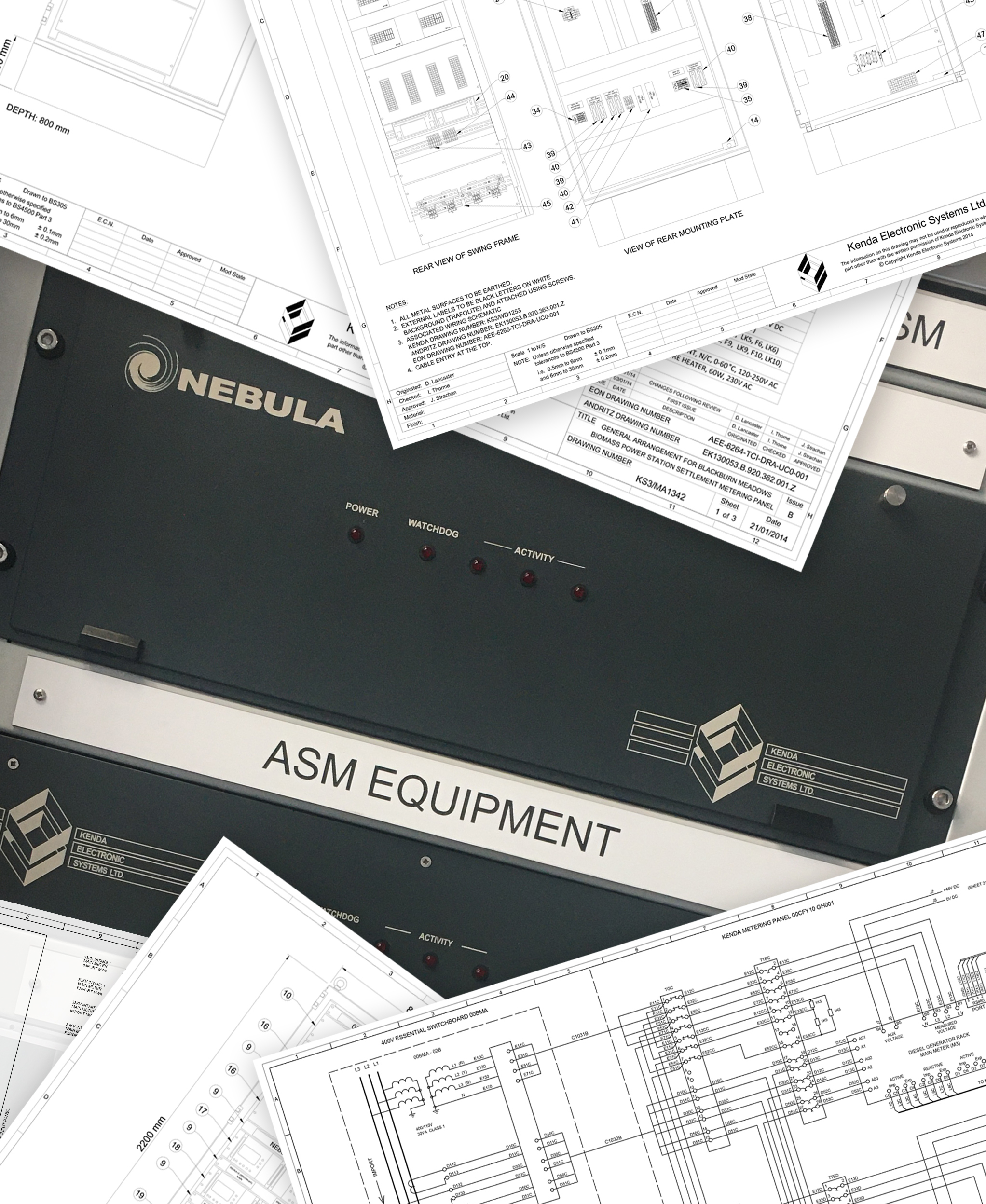

Metering Panel Design and Manufacture

- Design and construction of panels to industry standards

- System Integration: outstations, energy meters, transducers, data loggers,

meter processors, transducers, flow computers, event loggers, test terminal

blocks, fuses, links, alarms, Dynamic System Monitoring (DSM), Phasor

Measurement Units (PMU), Power Quality Monitoring (PQM)

- Measurement of: energy, temperature, pressure, distillate, condensate,

water, steam (CHP plants)

- Construction: standard 42U high (600w x 600d, 800w x 600d, 800w x 800d)

cubicles, with swing frame

- Wall mounted units available

- Top or bottom cable entry

- Wire sealing facility on doors and front panels

- Wind Farms (Offshore / Onshore)

- Embedded Generation

- DNO Connections

- Grid Solutions

- Battery Storage Systems

Project Management

- Appreciation of Project Management

- Life Cycle: Initiation, Planning, Execution, Closure

- Plans: (e.g. Resource, Quality, Risk, Health, Safety and Environmental).

Created in accordance with criteria defined by ISO 9001:2015, ISO 14001:2015

and ISO 27001:2013 and ISO45001:2018 accredited procedures.

- Execution: on-going monitoring and control

- Communication: all relevant parties kept informed by relevant information at

the relevant time

- Document translation

- End to end project delivery

Drawings / Documentation

- Includes: Quality & SHES plans, Wiring Schematics, Mechanical Assemblies,

Label Drawings, FAT specifications, RAMS, Commissioning Schedules,

Proprietary Manuals

- All documentation and drawings issued under strict procedural instructions in

line with Kenda’s ISO 9001:2015 compliance

- Multi-lingual Support, documentation can be provided in any required

language, with previous experience of presenting operational/maintenance

manuals in both English and German

- Drawings in AutoCAD, Engineering Base formats

- Result is a complete audit trail of issued versions (tracked changes)

- These procedures are regularly vetted both internally and externally by BSI

Auditors

- All test equipment is calibrated in accordance with ISO 9001:2015 procedural

requirements & calibration certificates stored with records traceable to

United Kingdom Accreditation Service (UKAS) requirements.